Dragée

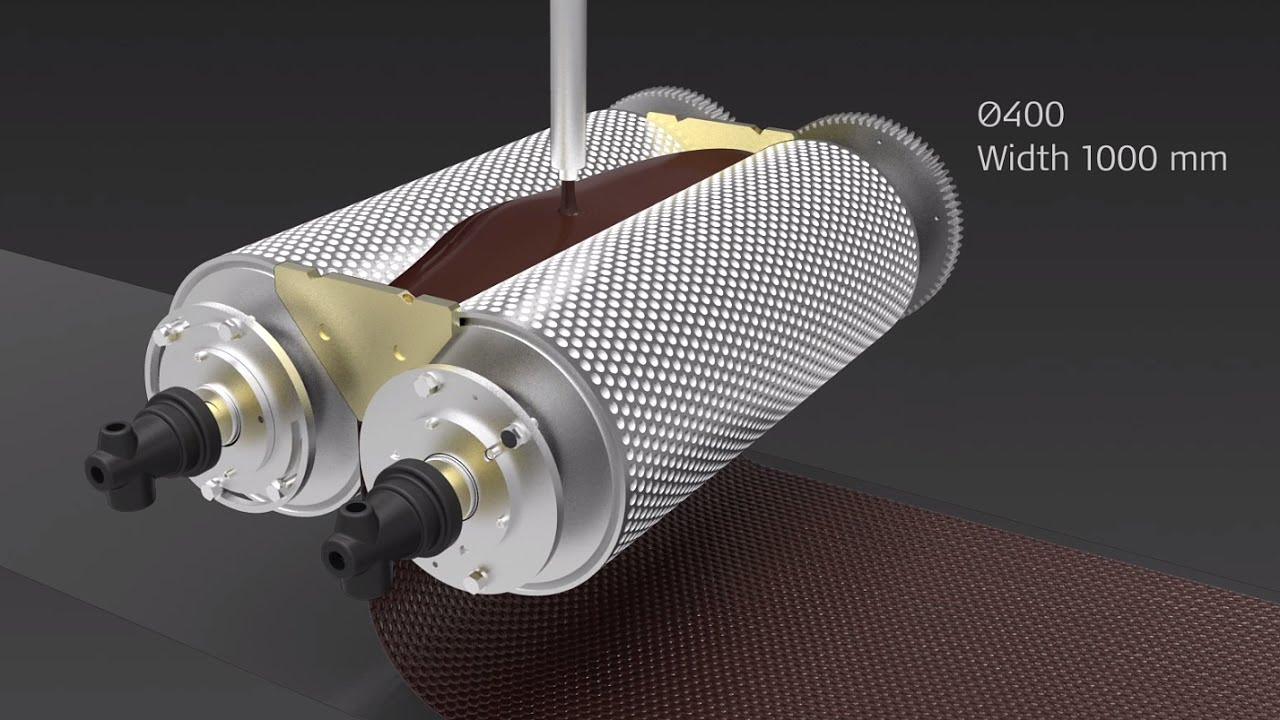

Refining

Chocolate ingredients are mixed and refined for a period of time. During refining it make conching by getting smells and acid out

Depositing & Forming

The lentils are then formed by depositing refined chocolate in a ball-shaped drum.

Cooling & Vibrating

It then proceeds to the cooling tunnel where it will cool and soften. Lentils vibrate with a rotary vibration in this essential step, which is used to separate the individual lentils and prevent them from joining up as they cool.

Coating

It is then subjected to the coating process, where sugar syrup, color, and optional ingredients are added.

Packaging

Once the chocolate lentils are properly coated, cooled they are packaged into bags, boxes, or other containers to protect the chocolate lentils, maintain their freshness, and make them ready for distribution and sale.