Wafer Production

Ingredient Preparation & Mixing

The first step is to gather and prepare the necessary ingredients. These typically include flour, sugar etc.The ingredients are then mixed with water this forms a smooth batter.

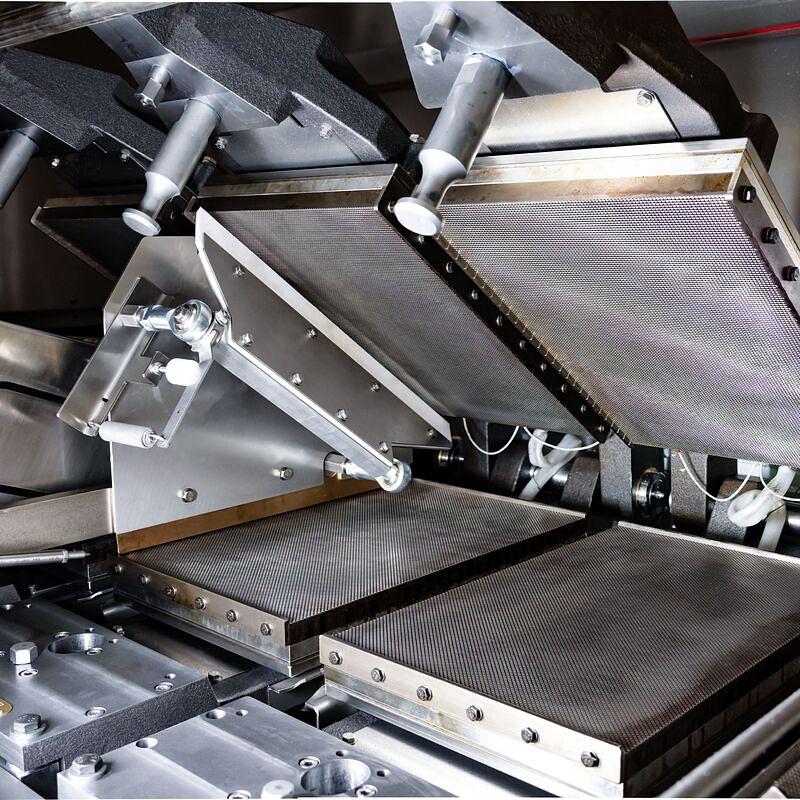

Baking

The batter is poured onto wafer baking plates. These plates are typically heated and patterned to create the familiar waffle-like pattern on the surface of the wafer.

Cooling Filling

After baking, the wafer sheets are cooled on conveyors or racks. This cooling step prevents the wafer from becoming too soft and allows it to maintain its crispness. Once cooled the wafer sheets are filled and stacked according to # of layers needed.

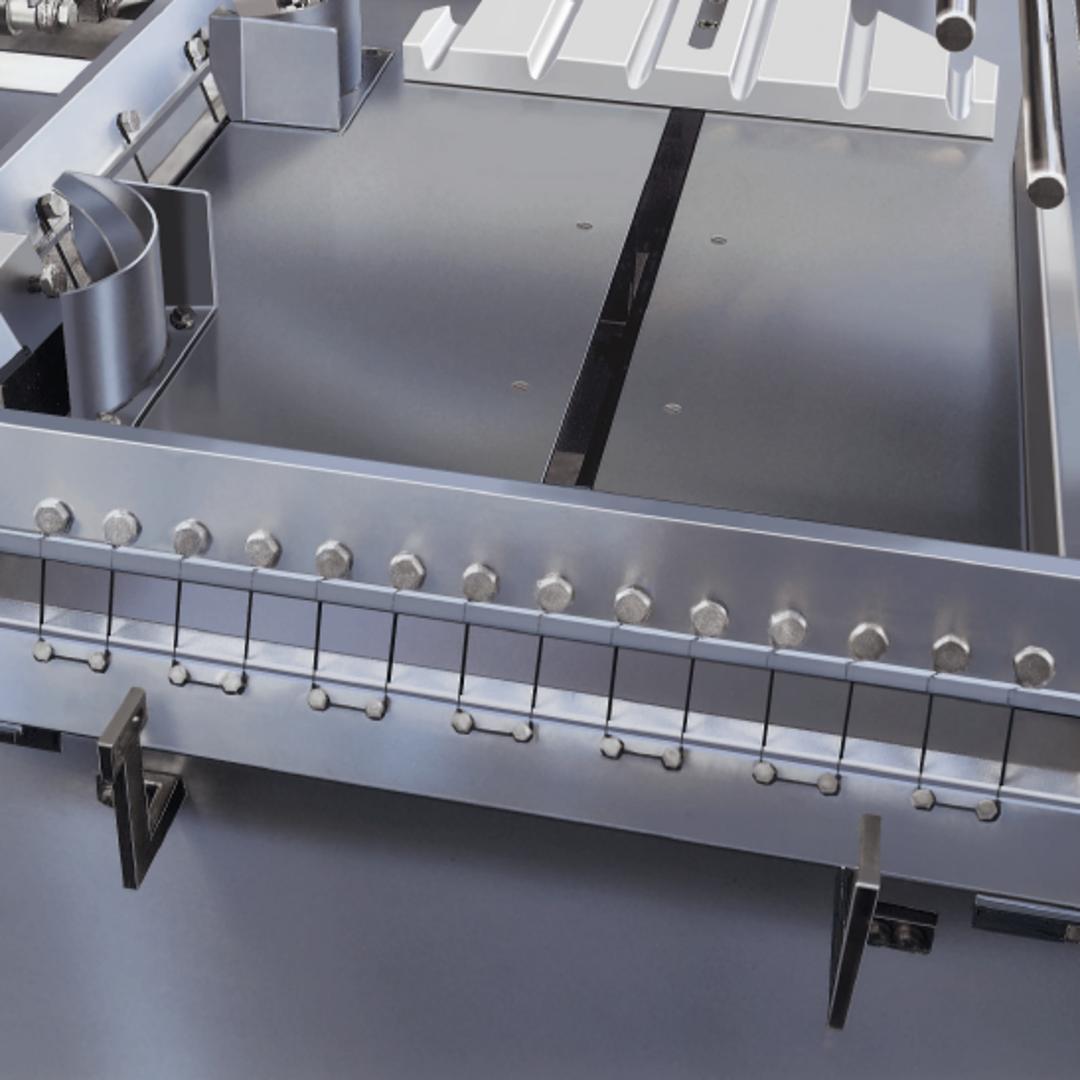

Cutting

The large wafer sheets are cut into the desired shape and size. Common shapes include rectangles, squares, or circles, depending on the type of wafer product being produced

Enrobing

If desired the wafer bar can be enrobed with chocolate then cooled to get its final shape.

Packaging

The wafer products are packaged in various ways, depending on the specific product and brand such as flow pack type.